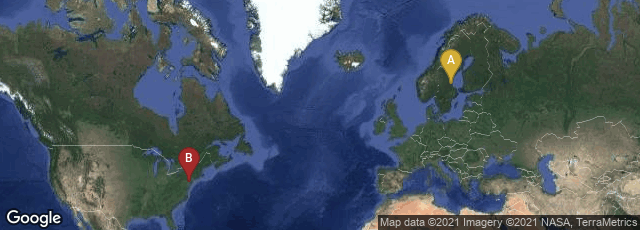

A: Söderhamn SV, Bergvik, Gävleborgs län, Sweden, B: Philadelphia, Pennsylvania, United States

In 1866 American soldier, chemist and inventor Benjamin Chew Tilghman developed the sulfite pulping process for the manufacture of paper from wood pulp, receiving the US patent on the use of calcium bisulfite, Ca(HSO3)2, to pulp wood in 1867. The first mill using this process was built in Bergvik, Sweden in 1874. It used magnesium as the counter ion and was based on work by Swedish chemical engineer Carl Daniel Ekman.

"The soda process was for many years the only practical process for pulping of straw, wood, and similar fibrous materials. However, in 1866, 1867, and 1869 the American chemist Benjamin Chew Tilghman of Philadelphia was granted British and American patents on a new process of pulping of wood or other vegetable fibrous substances. This process involved essentially the heating, under pressure, of lignified fibrous material with an aqueous solution of sulfurous acid, with or without the addition of sulfite of an alkali such as calcium sulfite or bisulfite. These patents were the results of extensive experiments conducted by Benjamin Chew Tilghman in cooperation with his younger brother Richard Albert at the pulp and paper mills of W. W. Harding and Sons in Manayunk near Philadelphia" (Phillips, Benjamin Chew Tilghman, and the Origin of the Sulfite Process for the Delignification of Wood, J. Chem. Educ., 1943, 20 (9), p. 444, DOI: 10.1021/ed020p444).

Throughout the 19th century it was increasingly necessary to find workable substitutes for scarce linen rags, the supply of which could not possibly keep up with the growing demands for paper. While the production of paper from wood pulp enabled greatly increased production, the bleaching agents used in this new process reduced the longevity of paper. The pulping, bleaching, and sizing processes generated hydrochloric and sulfuric acids, which over time resulted in brittleness and deterioration of paper, and the possible loss of information.