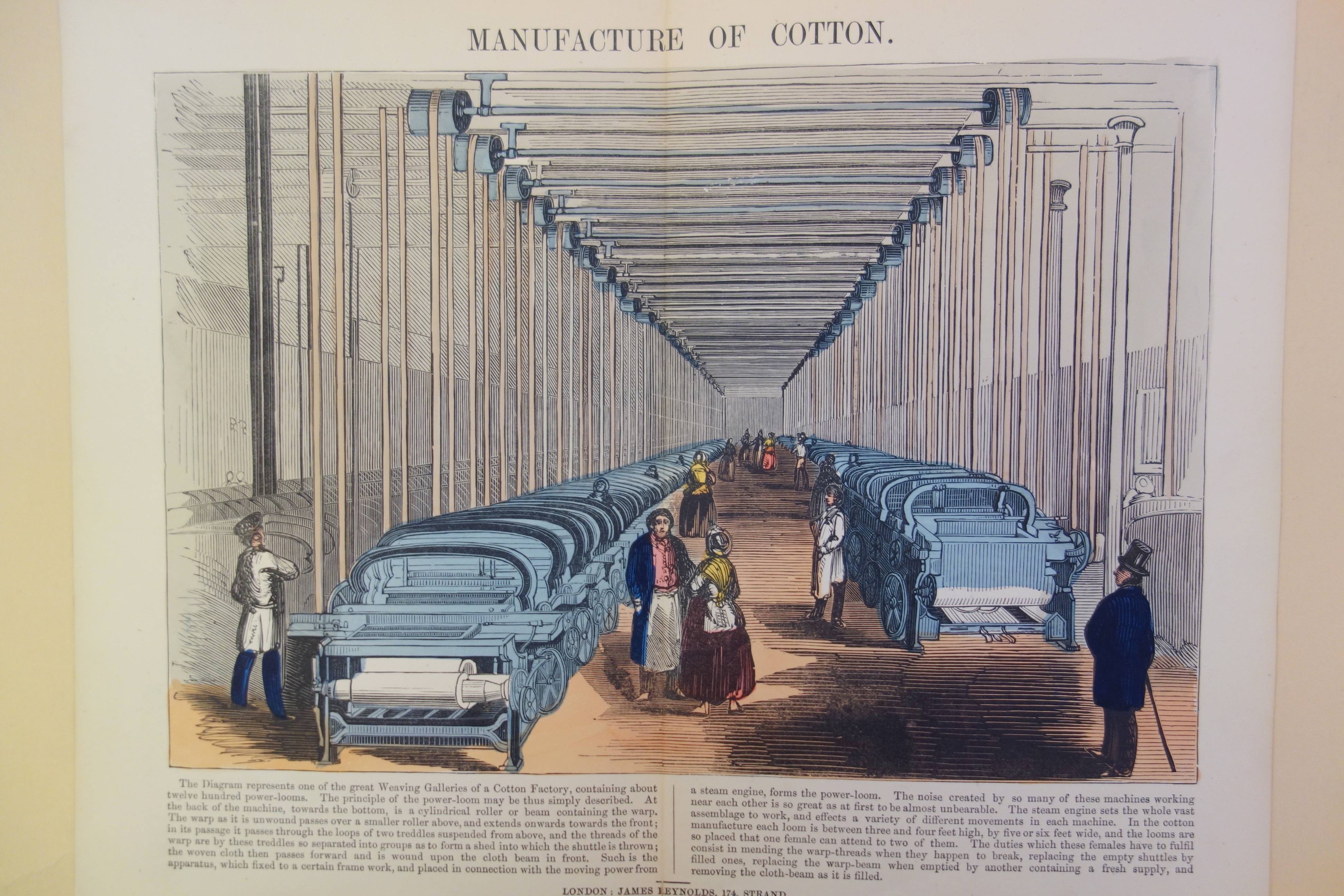

Roberts looms in operation at a cotton mill. The long caption to this hand-colored print is unusually informative. It reads:

"The Diagram represents one of the great Weaving Galleries of of a Cotton Factory, containing about twelve hundred power-looms. The principle of the power-loom may be thus simply described. At the back of the machine, towards the bottom, is a cylindrical roller or beam containing the warp. The warp as it is unwound passes over a smaller roller above, and extends onwards towards the front; in its passage it passes through the loops of two treddles suspended from above, and the threads of the warp are by those treddles so separated into groups as to form a shed into which the shuttle is thrown; the woven cloth then passes forward and is wound upon the cloth beam in front. Such is the appratus, which fixed in a certain frame work, and placed in connection with the moving power from a steam engine, forms the power-loom. The noise created by so many of these machines working near each other is so great as at first to be almost unbearable. The steam engine sets the whole vast assemblage to work, and effects a variety of different movements in each machine. In the cotton manufacture each loom is between three and four feet high, by five or six feet wide, and the looms are so placed that one female can attend to two of them.The duties which these females have to fulfill consist in mending the warp-threads when they happen to break, replacing the empty shuttles by filled ones, replacing the warp-beam when emptied by another containing a fresh supply, and removing the cloth-beam as it is filled."