A particularly clear reduction of Bacon & Donkin's view of their rotary printing machine as used for their patent.

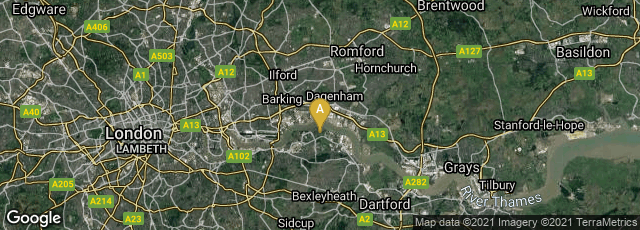

A: London, England, United Kingdom

Around 1820 the quantity of paper made by machine exceeded the quantity of paper made by hand. Besides lower cost, machine made paper had several advantages to printers who used the new printing machines. Chief among those advantages were that machine-made paper could be made in much larger sizes than hand-made, allowing books to be printed in 16 or 32-page signatures. Another advantage was the speed at which machine-made paper could be made. Knowing that mechanized paper mills could produce paper rapidly to meet whatever demand a printer might have alleviated the need to maintain several months' supply of paper on hand, thus reducing capital investment.

The earliest discussion and illustrations of papermaking machinery in English, other than the patents involved, that I have found is in civil engineer and writer John Nicholson's The Operative Mechanic, and British Machinist; being a Practical Display of the Manufactories and Mechanical Arts of the United Kingdom (London: Knight and Lacey, 1825), 365-377. In this work on industrial processes Nicholson ignored the traditional hand-made process of making paper, and featured mainly Dickinson's process and reproduced Dickinson's text images of his machine from Dickinson's patent.

Like his publisher, Knight and Lacey, Nicholson had a relationship with the London Mechanics' Institution, dedicating his book to its founder, George Birkbeck. It is possible that some of the material in Nicholson's volume was adapted from the Mechanics Magazine, also published by Knight and Lacey beginning in 1823.

With respect to printing presses, Nicholson wrote about the Stanhope press, and the Ruthven flatbed press. He also recommended the Bacon and Donkin rotary press, providing a particularly good compact image of that machine.